Commitment to Quality Quality

Sarkar Tactical is passionately committed to achieving the highest quality standards in the design, manufacture and delivery of protective systems and tactical gear. From living up to our ISO 9001-2008 certification to employing the most robust product development processes, quality is embedded in everything we do.

Our Quality Assurance processes and the people that guide it, test everything from in-coming raw materials and sourced components, to final inspection and lot sampling. Labs located at each of our manufacturing facilities ensure that our Ballistic Helmets, Vests and other tactical products are thoroughly tested throughout their development and manufacture ensuring that Sarkar products consistently exceed the ballistic, environmental and quality standards required by military customers around the world.

WORLD-CLASS MANUFACTURING Quality

Sarkar’s 16,000 square foot factory in El Paso, Texas is one of USA’s top ballistic manufacturing facilities. We are a complete armor manufacturer from moulding our helmets to stitching the vests. From first design to final manufacture, Sarkar exceed the highest standards.

With on-site quality assurance, product assembly, warehousing, and distribution, all mission critical processes remain in-house where they are constantly monitored and controlled by the technical team with one goal: to build product that exceeds Sarkar’s rigid ballistic standards, quality requirements, and delivery schedules.

All to ensure the highest performing product is delivered to soldiers when they need it—on time, every time.

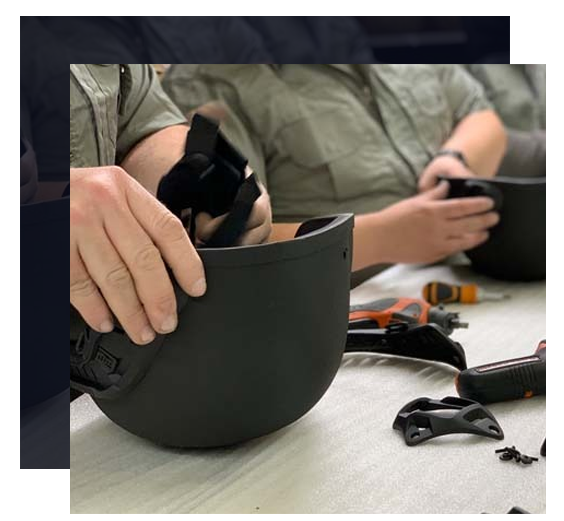

HELMET MANUFACTURING CENTRE HELMET

From flat fabric to our world class composite helmets, this cutting edge facility employs a highly adaptable and scalable approach to manufacturing, uniquely capable of running test samples one day and transitioning to full-scale production the next. Key to this ability is our unique composite manufacturing equipment with flexible tooling that can be quickly and accurately adjusted to meet a given portfolio: performance, dimension and weight requirements.

This facility houses advanced, in-house testing and quality assurance labs. Using this equipment, the components of each helmet are monitored throughout the manufacturing process then validated at the end of the pipeline—from dimensions and weight through to compression and impact testing.

IN-HOUSE TESTING CAPABILITIES TESTING

How do we know our products perform to the highest standards? Because we test them. Continuously. At our in-house and also outdoor field testing facilities where every system is systematically pushed to the limit.

Everytime you put on a Sarkar ballistic product, you have total piece of mind knowing that from the raw thread to the final finished article, everything has passed rigorous testing. In house controlled tests tell us only so much. For real world tests, we head out to our desert testing facility.

Have a look at some of our test videos and you will see at Sarkar, when we say we stand behind our product, we actually do!

Manufacturing videos videos

- Home

- Manufacturing